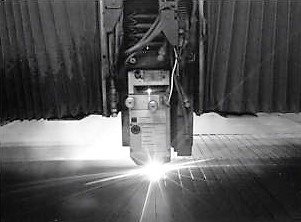

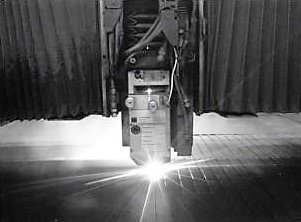

Laser cutting in Melbourne is one of the popular procedures for the cutting, marking and engraving the various physical objects. This process involves cutting metal and other materials by using a high-powered laser. Directed by 3D modelling software, this high-powered C02 laser beam is sent through a series of mirrors which gives us the ability to focus on the work zone. As the laser used is quite intensive, it can either cut or vaporise the metal and releases it through a high-pressure gas jet.

Let’s see some of the applications which are extensively used in not only Melbourne but also worldwide:

It’s widely used in the aerospace, automotive, electronics, semiconductor sectors. Some other applications are:

- In the medical industry

Laser cutting in Melbourne is also seen in the medical industry used for cutting purposes. For example, this procedure is used during laser surgeries, dental treatments, etc. This laser beam replaces the scalpel and gives the same functionality with increased efficiency, accuracy and with improved results. - For cutting different metals

Laser cutting is widely used in cutting all kinds of metals. Be it steel, tungsten, nickel, brass and aluminium – the laser can cut through everything. No matter the thickness of the metal, a laser can slice through it giving a smooth finish and clean edges. For example, consider car parts which are given a proper structural shape by this laser cutting. - For marking and engraving

Marking and engraving are the two popular applications to improve the aesthetics of any physical object. For instance, it’s used in the metal wall art, which is the trending decor for home interiors, garden and for other contemporary artworks. And also, it’s applied in engraving various designs on any kind of jewellery.

Other than these, companies provide laser cutting in Melbourne for cutting silicon, ceramics and other non-metals. For any of your laser cutting needs, don’t forget to consult the efficient and popular companies to give the best shape to your products. Search for those companies today and get highly accurate, reliable and versatile laser cutting.

Outdoor screen panels are the best concealer. Whether you want to hide something in your garden, add privacy to an area or create an eye-catching feature, outdoor Garden Screen Panels are the ultimate solution. Among all the options available, metal screen panels are the best as requires very less maintenance and an affordable option as compared to brick walls.

Outdoor screen panels are the best concealer. Whether you want to hide something in your garden, add privacy to an area or create an eye-catching feature, outdoor Garden Screen Panels are the ultimate solution. Among all the options available, metal screen panels are the best as requires very less maintenance and an affordable option as compared to brick walls.